Tool path not compensated (above) and compensated (below), by the specified cutter radius Offset Commands Both are applied to a particular contour, with the cutter diameter shown as well, including its positions. One is not compensated, the other is compensated. The illustration in Figure 30-1 shows two types of a tool path. This is called the equidistant tool path. Whether used on a CNC machining center or on a CNC lathe, the cutting tool edge must always be tangent to the contour, which means the tool motion has to create a path where the center point of the cutter is always at the same distance from the contour of the part.

During contact with material, the cutting tool edge must be in contact with the programmed part contour – not its centerline.Īctual toolpath for all contouring operations is always equivalent to the cutting tool motion.

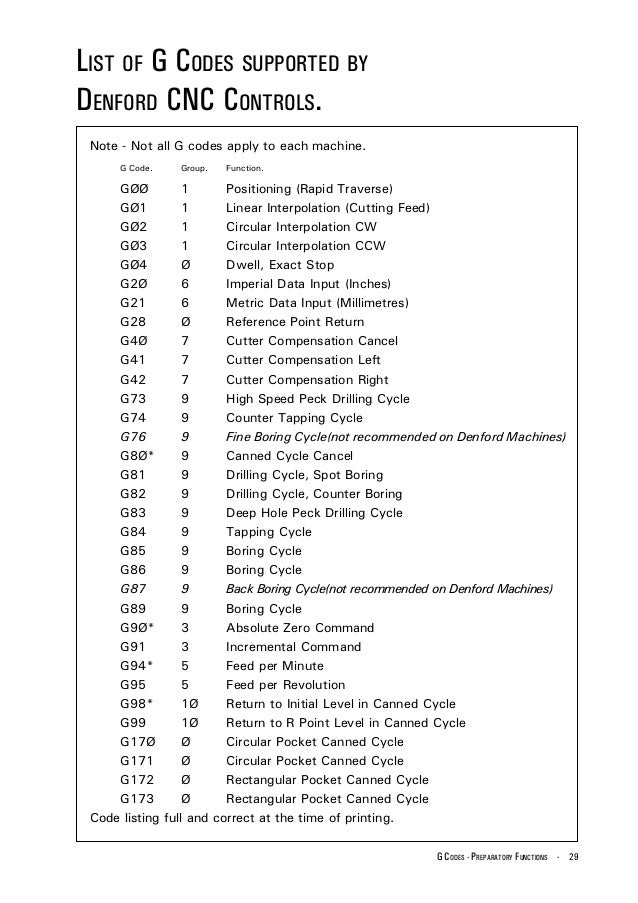

Although centerline programming is a very convenient method for program development, it is also a method unacceptable for machining. In either case, keep in mind that this type of programming always uses the spindle centerline as the X-Y or X-Z tool movements. These motions between contour change points can be programmed in millimeters or inches and they can use absolute value positions or incremental distances. For both types of machining, each contour element requires a single block of cutting motion in the program. For turning applications, either the X-axis or the Z-axis, or both axes can be used to face, turn or bore a contour. In this article, we describe tool radius offset commands which is called G41 and G42 codes CNC machining centers ( Milling ) with all details and examples.Ĭontour of a part – also known as a profile – is normally programmed for milling applications by establishing the depth in Z-axis first, then moving the cutting tool individually along the X-axis, Y-axis, or both axes simultaneously.

0 kommentar(er)

0 kommentar(er)